JS5 Rey

Open Class Single Seater

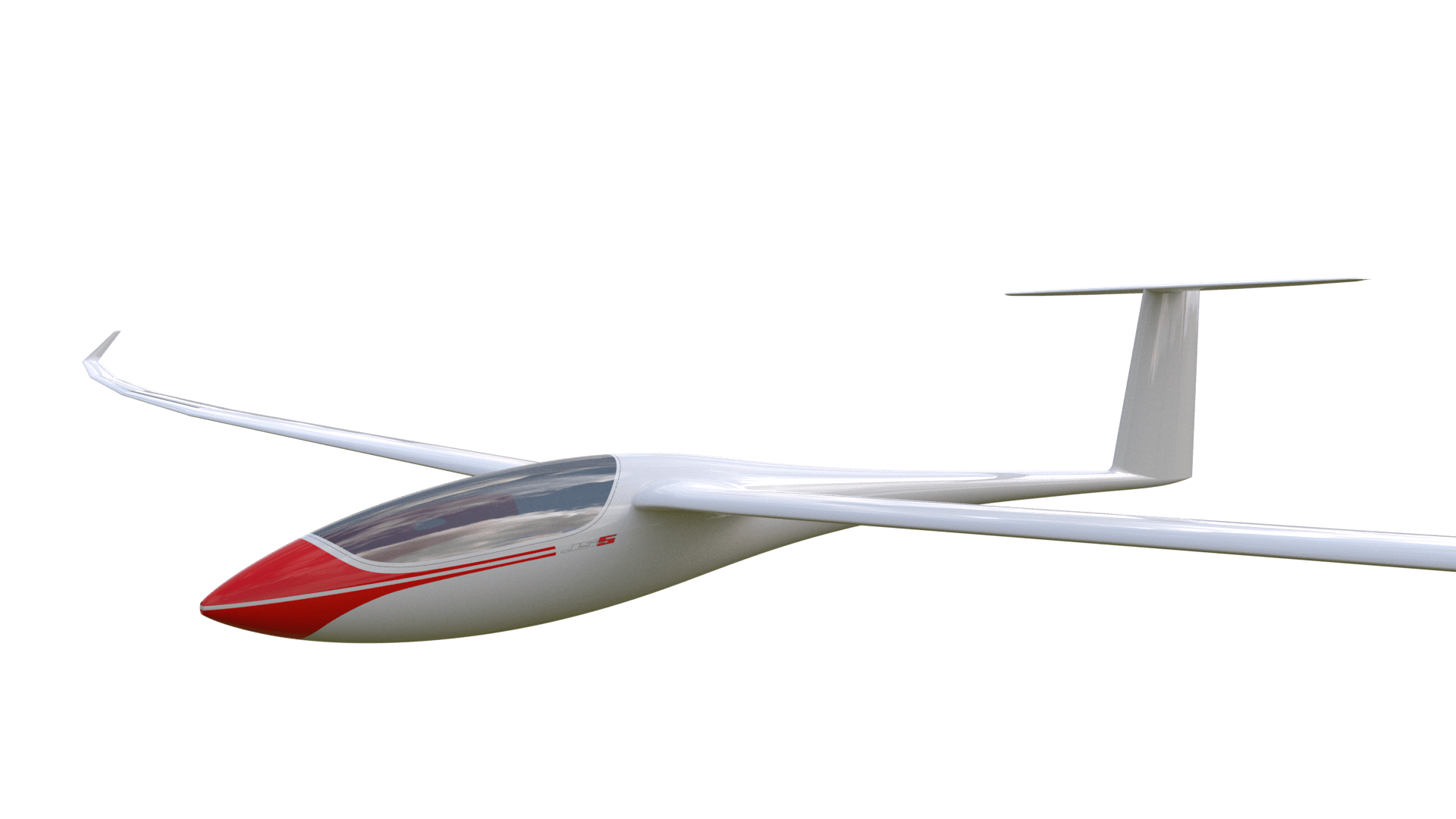

The JS5 Rey — a world-class 24.2 m Open Class sailplane, offered as pure or with advanced propulsion options for ultimate performance.

The JS5 Rey is a high-performance Open Class sailplane, fully-equipped in its standard configuration.

Optional propulsion systems include the JET Sustainer (MD-TJ42) and the Self-Launching SOLO 2635 02i NEO Silent engine.

The JS5 is designed to be the best Open Class sailplane in the world.

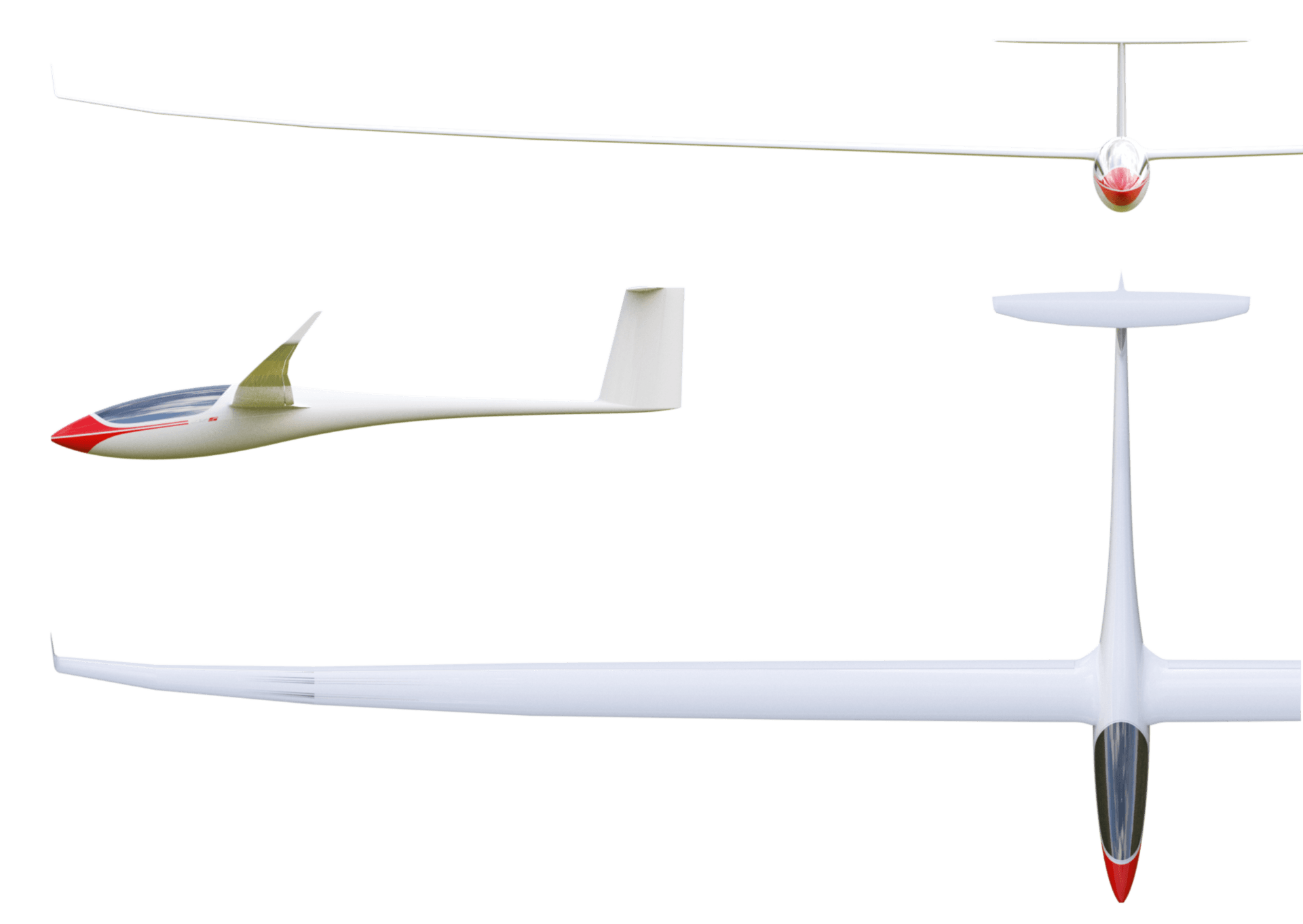

Dr. Johan Bosman and his team collaborated closely with the structural engineers to determine the optimal wingspan, carefully considering structural and material limitations. Through this process, an optimum wingspan of 24 meters was identified for Open Class performance.

Extending the wingspan beyond 24 meters introduces structural and stiffness challenges that begin to negatively affect performance, further confirming that 24 meters is the ideal span for a top-performing aircraft.

The completely new designed smaller inner wing, combined with the JS2’s optimized fuselage design, makes the JS5 a Open Class king in 24.2 m configuration.

The JS5 has been designed to climb well in small broken thermals as well as to excel at high speeds. The lightweight structure allows improved ground handling but also make the glider adept at utilizing the last thermals of the day.

- Control surface gaps sealed with the Teflon/Mylar system.

- Boundary layer control through blowholes or zig-zag tape.

- Cockpit airflow is regulated with an integrated air extractor.

- Integrated bug wiper garages.

- Total energy and Pitot-static probes by Airsense, mounted at the tailplane extremities.

- Integrated water ballast tanks in main wings – 190 l (50.2 gallons)

- JS bug wipers are operated by the CuttingEDGE Bug Wiper Winder system.

Wingspan | 24.2 m | 79 ft |

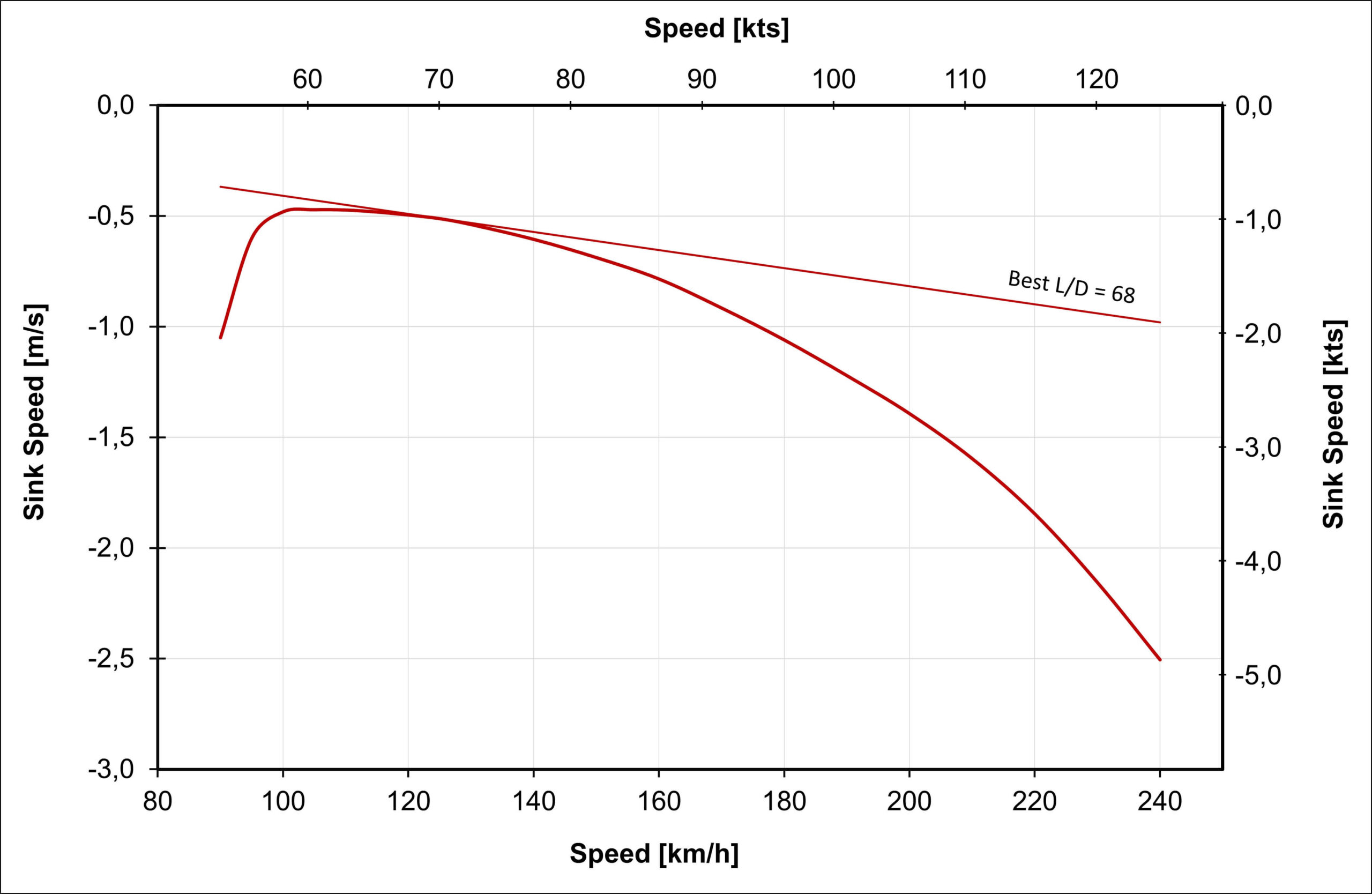

Best LD | 69:1 | 69:1 |

Minimum sink | 0.45 m/s | 88.60 ft/min |

Sink rate @ 200 km/h | 1.32 m/s | 260 ft/min |

Max Wing loading | 60.60 kg/m² | 12.41 lbs/ft² |

Min Wing loading (90kg pilot) | 47.80 kg/m² | 9.80 lbs/ft² |

Water ballast capacity | 199 I | 52.60 US gal lqd |

Note that performance values are representative and will vary slightly depending on actual aircraft configuration.

Safety has always been a non-negotiable priority in all of JS’s products, and the JS5 is no exception.

Throughout the design process, multiple iterations of the fuselage structure were explored to minimize the glider’s weight while still fully complying with the CS-22 certification standards.

To further enhance safety, the JS5 is equipped with a standard fire warning system, which immediately alerts the pilot to any potential fire risk—allowing for prompt and appropriate action to be taken without delay.

Max Speed VNE | 270 km/h | 145.8 kts |

Max Rough Air Speed VA | 193 km/h | 104.2 kts |

Max Aerotow Speed VT | 180 km/h | 97 kts |

Cockpit Crash Resistance | 9G | 9G |

- Automatic controls, including the water system.

- Limit switches for landing gear & airbrakes.

- Water dump sensor.

- Hydraulic disc brake activated by a dedicated brake lever on control stick.

- Powerful airbrakes, lockable in different settings.

- DynafoamTM energy-absorbing seat cushion.

- MH CFF-480 O2 cylinder holder with quick release.

- Fire warning system.

- Dolba transponder antenna in the vertical fin.

- Strobe light in Fin.

- FlarmTM collision-avoidance antenna in fin.

The cockpit will be of similar layout as the JS3 – the largest performance glider cockpit in its class. Including easily removable covers for maintenance and sufficient space for additional oxygen.

Extensive time and effort has gone into designing a cockpit that has the space requirements the pilot needs but not compromising/impeding performance.

During the entire design phase of the aircraft the maintainability of the airframe received significant input and attention to ensure access to controls, electrical system and the engine system.

The following features have been redesigned from previous models to ensure the pilot has an even more comfortable flying experience:

In addition the canopy mechanism has been improved to accommodate hot and cold conditions. The design ensures that the canopy front lip always closes, improving the performance of the glider by allowing undisturbed flow of air over the canopy.

Larger areas for the handles to turn on ensure smoother operation. Cut-outs in frame improve serviceability of the internal components. Designing floating rear supports in the cockpit frame to allow for temperature differences on the ground but allowing for the canopy to return to the optimal position once cooled down in the air.

The fundamental improvements on the JS2 water system includes increase in torsional stiffness of the tubes between the outboard section and the inboard section and increased travel range for the outer tips allowing for faster dumping of ballast. This also reduces the required travel in the fuselage to activate the water system. The water system doesn’t function sequentially but independently from one another between the outer and inner panels.

The design allows for both the inboard dump valve as well as the outer dump valve to be pushed up independently when dumping of water from one of the tanks is required.

The instrument panel has been moved closer to the pilot to make reaching the instruments easier.

This change has made it possible to increase the area of the instrument panel slightly compared to the JS3. The amount of shade on the intrument panel has been increased by increasing the lip length of the coaming.

Changing the routing of the wiring from the side channel to below the binnacle allows easier access for maintenance and less tension on the wires routed to the binnacle. This method also allows for a dedicated pathway for venting.

The seatback adjustment design has been changed to allow the pilot adjustment while in flight the geometry of the attachment points have also been changed to ensure easier movement of the seatback in its lower attachment points by changing the attachment surfaces to parallel.

The rerouting of the electrical wiring has made it possible to incorporate a dedicated venting channel with the shortest route from the source of the air to the binnacle. The design intention is still to allow for the airflow to help with the cooling of the intruments while providing the pilot with demisting of the canopy in humid conditions. The demisting valve is operated manually in the same way as the JS3 (from the instrument panel with a push pull knob.)

Max Cockpit Weight | 115 kg | 254 lbs |

Maximum Size Pilot | 2.03 m | 6 ft 8″ |

Airbrake Locking Forces | ∼ 15 daN | ∼ 15 daN |

Cockpit Shoulder Width | 525 mm | 525 mm |

Landing Gear Retracting Forces | ∼ 15 daN | ∼ 15 daN |

Inner Wing Panel Weights | < 110 kg | 234 lbs |

- In-flight electrically adjustable rudder pedals.

- Adjustable seatback with headrest.

- Canopy side window with air scoop.

- Green tinted canopy for increased UV protection.

- Forward opening canopy for comfort.

- Cockpit side vent with ventilation control.

- Leather cockpit interior upholstery with storage

- pockets.

- Tool bag including lubrication tube and rigging tools.

- Canopy cover and tail dolly.

- Serviceable tail battery.

The developmental goal of the JS5 was to design the ultimate open-class glider. Therefore the optimum wingspan needed to be determined. Through extensive calculations, while considering material constraints, performance was accessed across various wingspans.

After multiple iterations, calculations revealed that the optimal performance peak was achieved with a modest wingspan of 24.2 meters.

The smaller wingspan does not only suggest superior performance but also provides advantages in terms of in-flight handling and ground operations.

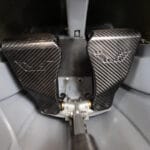

SOLO Fuel Injection Self Launcher System

The retractable pylon system features the SOLO® 2625-02i NEO Silent — a liquid-cooled, fuel-injected twin-cylinder engine delivering 50 kW (64 hp). Paired with an in-house designed propeller, it offers outstanding take-off and climb performance of. The system runs smoothly with reduced vibration and exceptional reliability, providing efficient power to bring you home — even over long distances.

JET Sustainer System

The MD TJ-42 Jet Sustainer System is the perfect match for JS gliders. Its performance and seamless integration ensure a smooth, effortless experience for the pilot. Operation is as simple as it gets—just one switch and a throttle dial. There’s no increase in workload and no noticeable performance loss with the jet extended. Reliable, efficient, and remarkably easy to use.

The JS5 Rey is Jonker Sailplanes’ latest high-performance sailplane, designed for advanced cross-country flying and competition. It combines cutting-edge aerodynamics with lightweight composite construction to deliver exceptional glide performance, handling, and efficiency.

Yes, the SOLO engine allows powered flight and self-launch capability.

The SOLO engine is designed to be lightweight and vibration-free, ensuring excellent glide ratios and handling even when powered, without compromising soaring performance.

The SOLO 2625 O2i NEO engine runs on standard automotive or aviation gasoline, designed for smooth, vibration-free operation and reliable performance.

Currently, the JS5 Rey is only available with the SOLO 2625 O2i NEO combustion engine, a 50-horsepower, twin-cylinder engine offering smooth, reliable powered flight. A RES (electric) version may be considered in the future.

For now, the JS5 Rey comes with a 24 m wingspan. Later, 18 m wingtips will be available for pilots who prefer a more compact, competition-friendly configuration.

The JS5 Rey is certified under EASA CS-22 and applicable national airworthiness regulations. Certification is managed via M&D Flugzeugbau, our EASA-approved Design Organisation and Type Certificate holder. All EASA-certified JS5 aircraft undergo final inspection and handover preparation in Europe.

Jonker Sailplanes collaborates with M&D Flugzeugbau, DG Aviation, and other premium partners to provide full service, spare parts, inspections, and technical guidance for the JS5 Rey.

The information and specifications presented on this website are provided for general guidance only and are subject to change without prior notice. While due care has been exercised in compiling this material, Jonker Sailplanes accepts no responsibility or liability for any errors, omissions, or inaccuracies. All performance data, masses, and figures are theoretical estimates and may vary in practice. Specifications and equipment may change without prior notification.