For today’s pilots, peace of mind is essential—especially after long flights or demanding competition days.

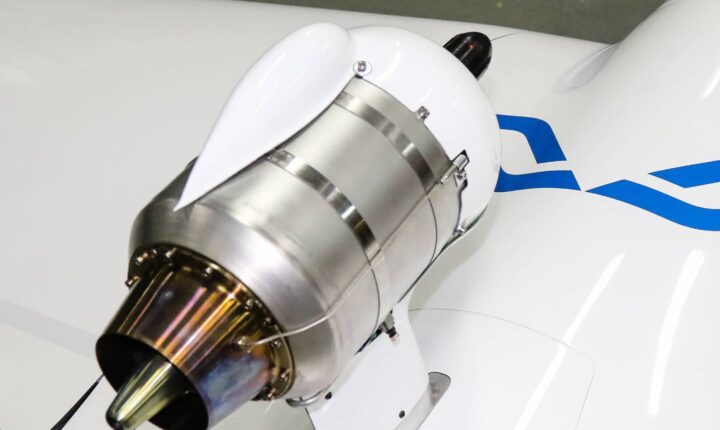

The JS-MD partnership delivers a modern solution that combines the reliability of the MD-TJ42 JET engine with the performance of a high-end sailplane.

This cutting-edge, lightweight system weighs just 17 kg and integrates seamlessly, with no noticeable increase in drag or reduction in glide ratio. The intuitive, user-friendly interface ensures ease of use, while offering impressive climb performance and straight-line thrust.

With just the flick of a switch, you’re a jet pilot.

The Jet system can be installed in the JS1, JS3, JS4 and JS5.

Engine | MD-TJ42 |

Manufacturer | M&D Flugzeugbau GmbH |

Maximum RPM | 97000 |

Idle RPM | 30000 |

Thrust at Maximum Rotary Speed | 40 daN (90lbf) (approximate thrust) |

Fuel Consumption at Max Thrust | 65-69 I/h (22.3 US gph) (MSL and ISA condition) |

Compression Ratio | 1:3.8 |

EGT at Max RPM | 790°C (1472°F) |

Complete System Weight – No Fuel | 17 kg (37.5 lbs) |

Fuel Capacity | JS1 – 42 liters (11.1 gal US) JS3 – 22 liters (5.8 gal US) |

- Single-spool jet turbine.

- Two-stage axial-centrifugal, stator-less compressor with a compression ratio of 1:3.8.

- Cannular combustor with multiple fuel injectors and combustion zones contained within a single annular casing.

- Glow-plug ignition system, used exclusively during start-up, igniting only the top combustion zone.

- Convergent nozzle.

- Front-mounted, direct-drive electric starter motor used for initial spool-up.

- Fully automated digital engine control (FADEC) system, operated by a single switch and digital

- RPM throttle control, including a ‘full auto start’ mode.

- Single Ø57 mm (21⁄4-inch) color Engine Display Unit (EDU) for system and throttle control, displaying RPM, EGT, fuel level and flow, as well as battery voltage and capacity.

- Engine and mechanical systems mounted in a removable monocoque carbon fibre box for easy maintenance.

- Fuselage mounted fuel tanks with integral fuel quantity sensors and filters.

- Engine extension/retraction via electric linear actuator with mechanical sequencing to close engine bay doors in both positions.

- Battery-powered, self-contained on-board refuelling system with fuel filler connector integrated into the engine box.

There is no increase in workload, only a single switch and throttle dial, and there is no noticeable performance loss with the jet extended.

The efficiency of the Turbo Jet increases with altitude. With a saw tooth flying profile at an altitude of 2000m (±6560ft) a range of 240 km (149 miles) can be obtained with the JS1 and 150 km (93 miles) with the JS3.

Maximum Power is achieved in less than 40 seconds from deployment of the system.

Visit M&D’s website to view more performance data of the MD TJ-42.

In 2007, M&D Flugzeugbau, the manufacturer of Jonker Sailplanes’ jet engines, recognized the potential of a small turbine sustainer for gliders and developed a completely new engine designed from the outset for certification and in-flight starting. The result, the MD-TJ42, features a kerosene start-up system, eliminating the need for gas canisters and complex procedures, and can operate on both Diesel and Jet A1 fuel. Its engine and pylon are enclosed in lightweight fiberglass and aluminium cowlings.

The MD-TJ42 was first integrated into the JS1 in 2013, with EASA and SACAA Type Certifications following between 2015 and 2017. Today, with more than 250 certified units installed in the JS-MD 1, JS-MD 3. M&D is the largest and most experienced manufacturer of jet engines for sailplanes, with engines operating worldwide and proven reliable in all weather conditions.

The retractable pylon thrust system features the SOLO® 2625-02i NEO Silent — a two-stroke, 625cc inline twin-cylinder, liquid-cooled aircraft engine with electronic fuel injection and a dual-sparkplug high- voltage ignition system. This engine is paired with an in-house, optimally designed propeller, delivering impressive take-off and climb performance at maximum take-off weight (MTOW).

The new-generation electronic fuel injection system offers significantly improved fuel efficiency, allowing for approximately 1.5 hours of engine operation. This robust system delivers a power output of 50 kW (64 hp), with an expected climb rate of approximately 3 m/s.

The engine has been modified to significantly reduce vibrations by adding a balancing shaft to the original SOLO® 2625-02i NEO engine design. This enhancement delivers smoother operation, reduced wear, and improved overall performance, ensuring even greater reliability and comfort for the pilot.

Water-Cooled Two-Cylinder Engine | SOLO 2625-02i NEO Silent |

Compression Ratio | 9.5:1 |

Maximum Static Thrust | 120 daN (270 lbf) |

Maximum RPM | 6700 |

Max Continuous Power (6 600 rpm) | 50 kW (67 HP) |

Consumption at Maximum Continuous Power | 24.5 l/h (6.5 US gph) |

Fuel Quantity (3 tanks) | 44 I (11.6 US gal) |

Fuel | 2- Stroke mix, AVGAS 100LL |

Engine Weight | 24 kg (52.9 lbs) |

System Weight – No Fuel | ∼ 65 kg (143 lbs) |

- Two throttle bodies with fuel injectors managed by the Trijekt Engine Control Unit ECU equipped with the following duplex-redundant components: Engine speed sensor, throttle position sensor and injectors.

- External fuel pumps electronics unit allow ECU to monitor fuel pumps as well.

- Integrated 500W alternator and electric starter.

- Dual electronic high-voltage ignition, mapped ignition system.

- Dedicated 12v 15.6Ah sealed lightweight LiFePO4 engine battery.

- Integrated CAN-BUS communication and fault memory for error messages and problem diagnostics.

- Multiple V-belt belt drive with Propeller and engine RPM monitoring to detect belt slip.

- Pylon extension and retraction via developed actuator system with an integrated pylon positioning system. Automatic centering of propeller after shutdown.

- Automatic cooling and retraction after shutdown.

- Tuned stainless-steel exhaust with silencer.

- Fire warning system.

- Two-blade carbon-fibre 1.44 m [4.72 ft] diameter propeller.

Inside the JS2 fuselage, our engineering team has successfully integrated the SOLO® 2625-02i NEO Silent engine — achieving seamless performance without compromising the advanced aerodynamic models developed by our aerodynamicist, Dr. Johan Bosman. This means self-launch pilots can now enjoy the freedom of independent takeoff with no loss in aerodynamic efficiency or performance.

In following video, we take you behind the scenes to highlight the latest enhancements to the SOLO self-launch engine system (by adding a balancing shaft) — a lightweight, reliable, and high-performance power unit that enables effortless self-launching without external towing.

Discover how OnTrack Technologies and Jonker Sailplanes continue to push the boundaries of engineering excellence and innovation in modern sailplane design. As the primary development subcontractor for Jonker Sailplanes, OnTrack Technologies plays a crucial role in the design, development, and prototyping of Jonker’s next-generation gliders.

The SOLO 2625-02i NEO Silent, adapted by OTT, features an integrated balancing shaft that eliminates primary vibration forces found in older engines. Certified by Solo Aircraft Engines, it is the standard powerplant for all JS internal combustion self-launchers, offering reduced vibration-induced failures, smoother operation, and a consistently reliable flying experience.

To maximize performance within the compact fuselage, fuel is stored in both the fuselage and integral wing tanks, with a total capacity of 44 litres across three tanks. Fuel transfer is managed automatically via venturi pumps and a submersible fuel pump system, reducing complexity and increasing safety. The engine is mounted on a fixed frame with vibration damping, and a bottom-out extension system pushes the engine into position, minimizing stress on the spindle and fuselage while ensuring smooth deployment and retraction.

The Retractable Electric System (RES) functions not only as a sustainer but also as a self-launcher, up to a specified maximum takeoff mass. The high-voltage system is powered by two removable batteries, securely stowed within the fuselage.

Developed in partnership with the renowned SOLO Aircraft Engines, the system is engineered for comfort, safety, operational flexibility, and impressive performance. Fully automated and easy to operate, the RES allows power output to be smoothly adjusted via a rotary dial on the control panel.

Propulsion System | SOLO Electric Propulsion System 80400 |

Propeller Type | Technoflug KS-1C-120-R-065-S |

Maximum Static Thrust | 90 daN |

Maximum RPM | 4350 |

Max Power for Take-Off | 40 kW (2 batteries) |

Max Continuous Climb Power | 25 kW (2 batteries) |

System Weight (No Batteries) | ± 24 kg (53 lbs) |

Battery Type | Emectric 96-4 400 V |

Battery Configuration | 96S4P |

Battery Voltage | 270 V - 400 V |

Usable Energy (available energy decreases with high power settings) | 3.4 - 3.9 kWh per battery |

Battery Weight | 25 kg (55.1 lbs) |

Maximum Number of Batteries | 2 |

Maximum Power (MP) and Maximum Continuous Power (MCP) values reflect the electrical power delivered from the HV batteries as indicated on the DCU. The corresponding shaft power available at the propeller is approximately 15% lower.

- Pilot interface: Single switch controls both pylon extension and engine bay doors.

- Choice of battery configuration: Dual-battery or single-battery setup available.

- Automatic propeller centering after shutdown.

- Engine bay doors operated by an electric linear actuator, with control sequencing to automatically close the doors in both retracted and extended pylon positions.

- Two-blade carbon-fibre propeller, 1.2 m (3.94 ft) in diameter, optimally designed to match the battery, controller, and motor specifications.

- High-voltage system for reduced current flow and increased efficiency.

- Optional second battery pack for increased sustaining range or enhanced self-launch capability.

The RES delivers competitive performance with an excellent power-to-weight ratio. The system is designed for maximum flexibility, carefully optimized to meet the needs of both competition and leisure pilots.

For contest pilots, it allows a low minimum wing loading, with one battery installed and can be used in this case as a sustainer which will bring you safely home.

With two batterie installed the system is a powerfull self-launcher at a relatively high wing loadings—ideal for leisure flying.

The modular battery configuration offers unmatched flexibility in wing loading, accommodating a wide range of pilot preferences and mission profiles.

JS safety is not negotiable. Operating the RES system gives you the in-control-feeling combined with highly desirable man-machine-interface characteristics.

For safety reasons the two batteries weighing 25 kg each are located in the fuselage, and are removable for safe charging. The novelty of this design is that glider can be flown with the batteries removed, or with one or both batteries installed.

Standard Safety Features

- Removable batteries for our-of-sailplanes charging

- Automatic battery power connections

- Electrical (430 VDC) isolation monitoring

- Battery, motor and controller temperature monitoring

- Battery internal relay-safe handling, isolating high voltage from terminals

- Internal Current Sensor with Internal Fuses

- Independent fire warning (heat detection) system

Battery driven vehicles took the world by storm, and the general aviation is slowly catching up. No fumes of fuel, no oil leaks, no vibration, no engine noise, no breaking belts, no starter button. This all sounds extremely attractive… but where is the catch?

Clearly the energy density is not nearly as good as their petroleum counterpart and therefore battery installations are still heavy for the performance they offer, and they are not as yet well priced. The risk associated with battery fires is a reason for concern, and EASA is actively working on improved special conditions to ensure safe designs – don’t underestimate manufacturers headaches when it comes to certification of systems with large LiPo batteries.

Well-known aircraft engine producer, SOLO Aircraft Engines, was the major inspiration behind the retractable electrical propulsion system. SOLO used the JS3 fuselage to model their sustainer design in the “smallest possible modern fuselage”.

JS and SOLO studied the maximum performance of the system and realized self-launching may just be possible. The concept of having not only a sustainer, but also a limited self-launcher with removable batteries is very exciting.

Performance, masses and figures are estimations based on theoretical data only and may change without prior notification.